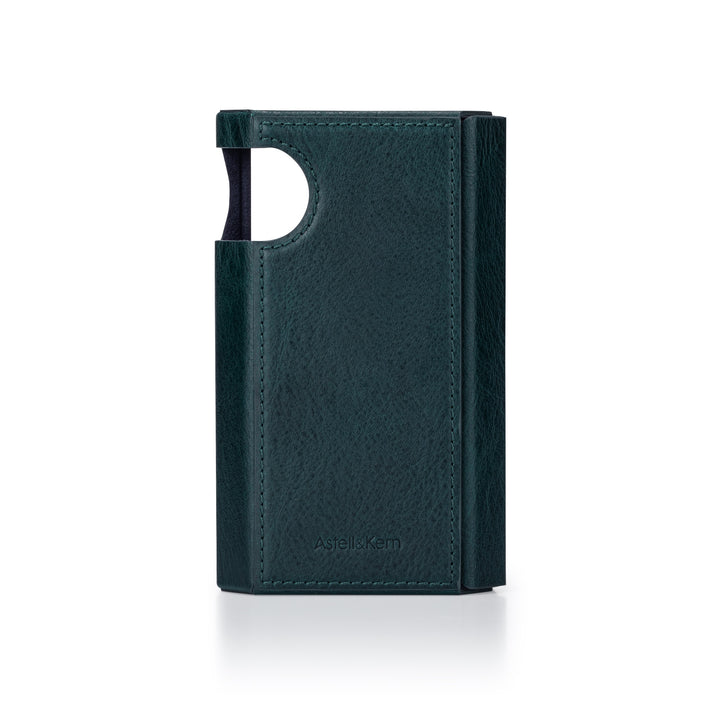

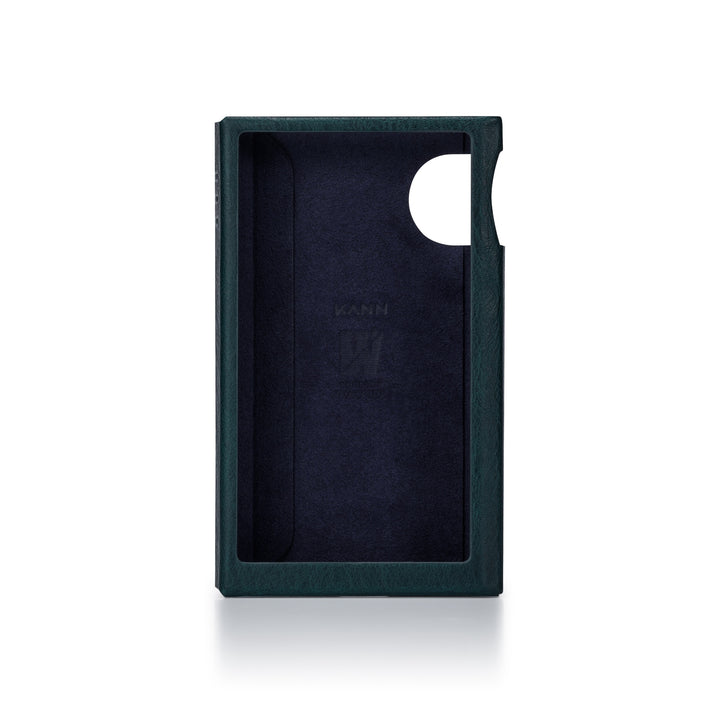

Astell&Kern uses the highest quality materials sourced from elite artisans to craft their official cases. Each case is designed to complete your experience, with a tight fit and thoughtfully matched colors.

These KANN Ultra cases are made of high-quality vegetable-tanned leather from Badalassi Carlo and Conceria Walpier, and boast a high degree of perfection that matches the design of Astell&Kern's KANN Ultra.

The case is available in ‘Black’ and ‘Blue/Green’ colors, and ensconces the Kann Ultra, providing excellent protection and the best grip with a perfect fit.

Leather from CONCERIA WALPIER

Established in 1973 in San Miniato, Tuscany, Italy, Walpier Tannery has been in business for three generations and has a long tradition of making leather products based on their highly regarded vegetable tanning processes. The tannery uses only 100% raw hide leathers imported from France and is a member of Vera Pelle, Italy’s association of vegetable-based leather tanners.

Walpier's vegetable tanning is a traditional leather processing method handed down from father to son for centuries in the Tuscany region. The tanning process usually takes 40 days and is a process only practiced by Italian tanners of the world.

In addition, leather products that undergo the vegetable-based tanning process continue to gradually tan over time according to the user's care, usage, style, etc., showing the user's lifestyle and making the product completely unique.

Leather from BADALASSI CARLO

Badalassi Carlo, a tannery founded by CARLO BADALASSI, who was a professor at a leather school in the Santa Croce region, has been producing leather for more than 40 years by integrating the traditional vegetable leather processing method developed in Tuscany with his unique theory and technology.

Vegetable leather processing is an eco-friendly leather manufacturing method that takes a long time to complete by tanning leather only with tannins extracted from plants.

The leathers of Badalassi Carlo use the vacchetta technique that was developed in Tuscany and then processed using vegetable oil for tanning.

The company pursues high quality by creating products using small batch, handcrafted traditional techniques rather than mass production. The tannery is highly regarded and preferred by famous manufacturers around the world who value the quality of leather produced.

Good quality, fits the Kann Ultra like a glove.